Smarter Rail Services

SKF bearing maintenance and management

services that improve railway reliability

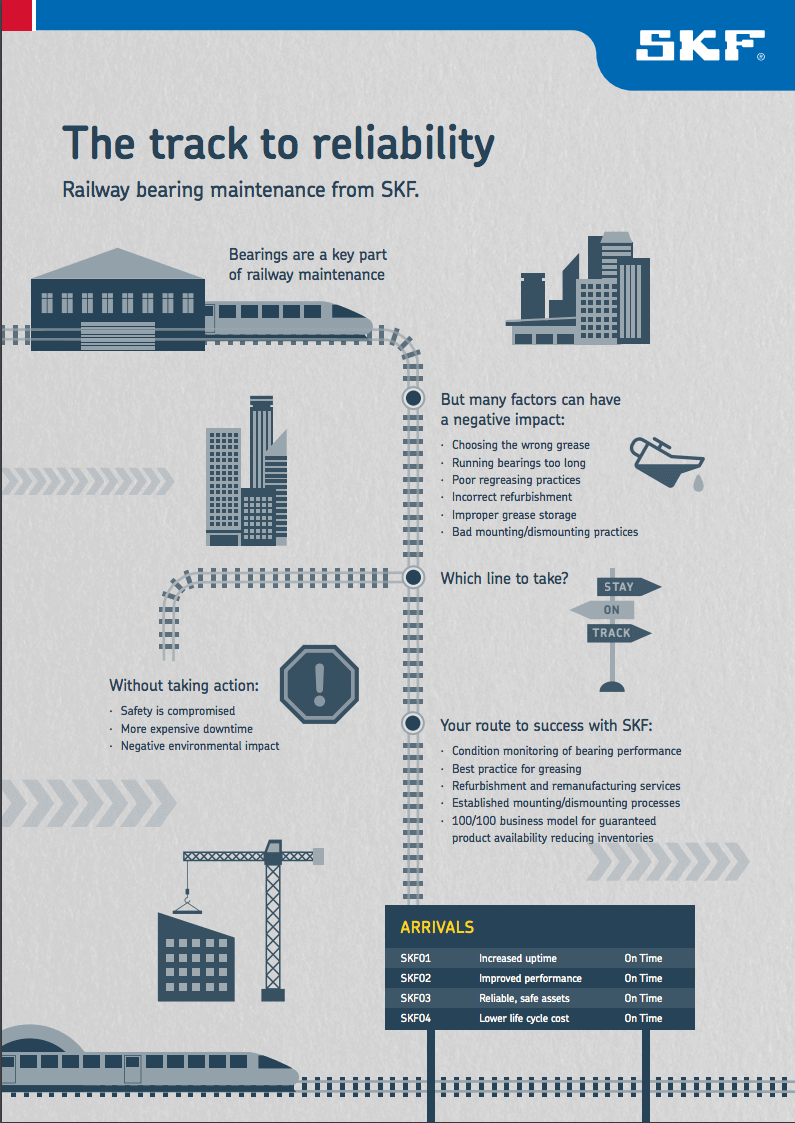

The overlooked elements of railway maintenance

Harsh operating conditions can damage bearings and reduce service life. Good maintenance of railway bearings help to improve rolling stock efficiency and increase service life. To make that happen, it’s important that every step of the process is considered, included often-forgotten elements like greasing, mounting and remanufacturing.

Best practice for best results

Good bearing maintenance is about more than the parts themselves: it’s about more efficient ways of working and following correct processes, too. Through our dedicated and first class railway remanufacturing facilities, you could reduce costs, utilise your resources and decrease environmental impact. In addition we can support you to:

- Detect failures in the field with condition monitoring

- Optimize the ways you select, store and apply grease

- Adopt new business models for more efficient management of spare parts

Minimize your risk of downtime with SKF

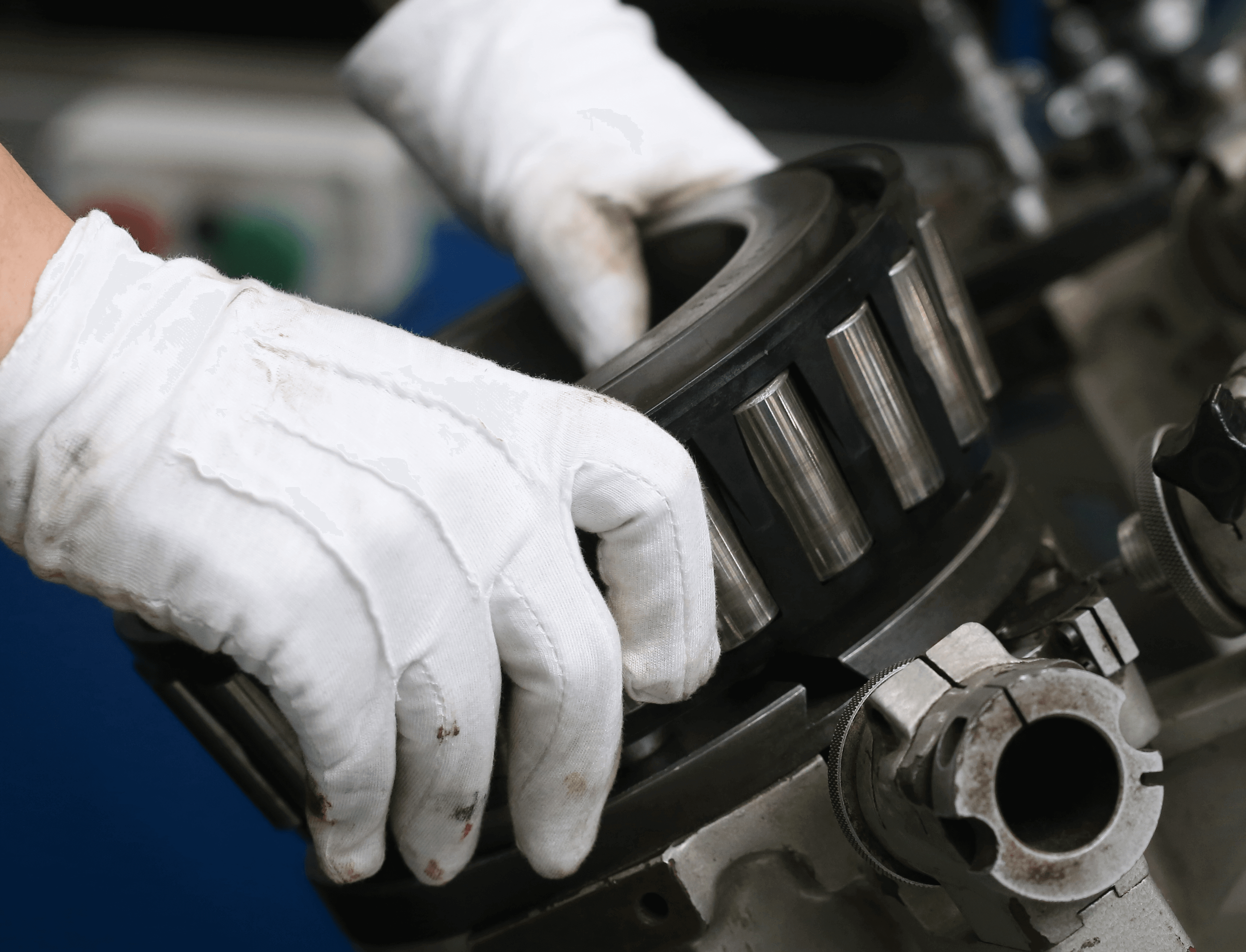

To reduce your risk and generate significant cost savings, SKF provide a range of services including:

- Bearing refurbishment operations and services

- Combining bearing remanufacturing with component upgrades

- Improving knowledge and care around mounting and dismounting

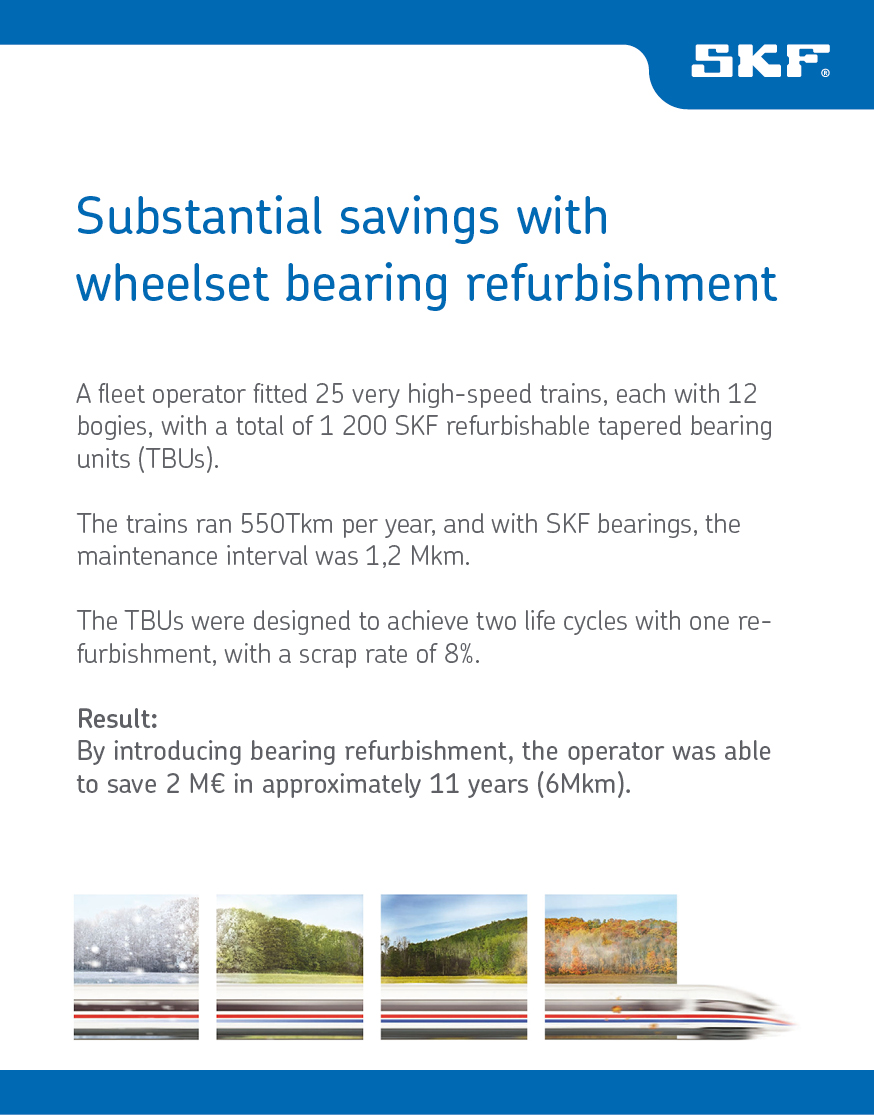

How much could you save?

Try our handy refurbishment

calculator to find out

Combined with our approach to business practices and processes, you can reap the benefits of a lower Total Cost

of Ownership, and a smoother, cheaper, more efficient operation that runs on time.

Take a closer look at the full suite of our rail-focused services in our whitepapers,

or get in touch with our expert team to discuss your specific needs.