70% reduction in MTTR for conveyor pulley bearings

The mining industry is a tough environment to work in. Extreme temperatures, heavy loads, abrasive dust and dirt and the fact that some bearings can be difficult to get to when replacing, can all be a challenge to say the very least. Safety hazards and unplanned downtime are constant risks that can impact worker wellbeing and the profitability of your business.

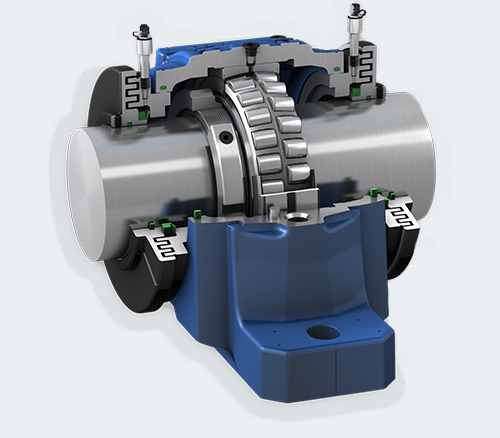

To address these issues, SKF’s Cooper split spherical roller bearings (open or sealed) are designed to be easily replaced in situ and require no changes to the shaft alignment or driveline – reducing mean time to repair for conveyor pulley bearings by 70%.

NB! If you’re looking for the ultimate in bearing protection, take a look at the SKF Three-barrier solution where contaminants must pass through three barriers to reach the bearing.

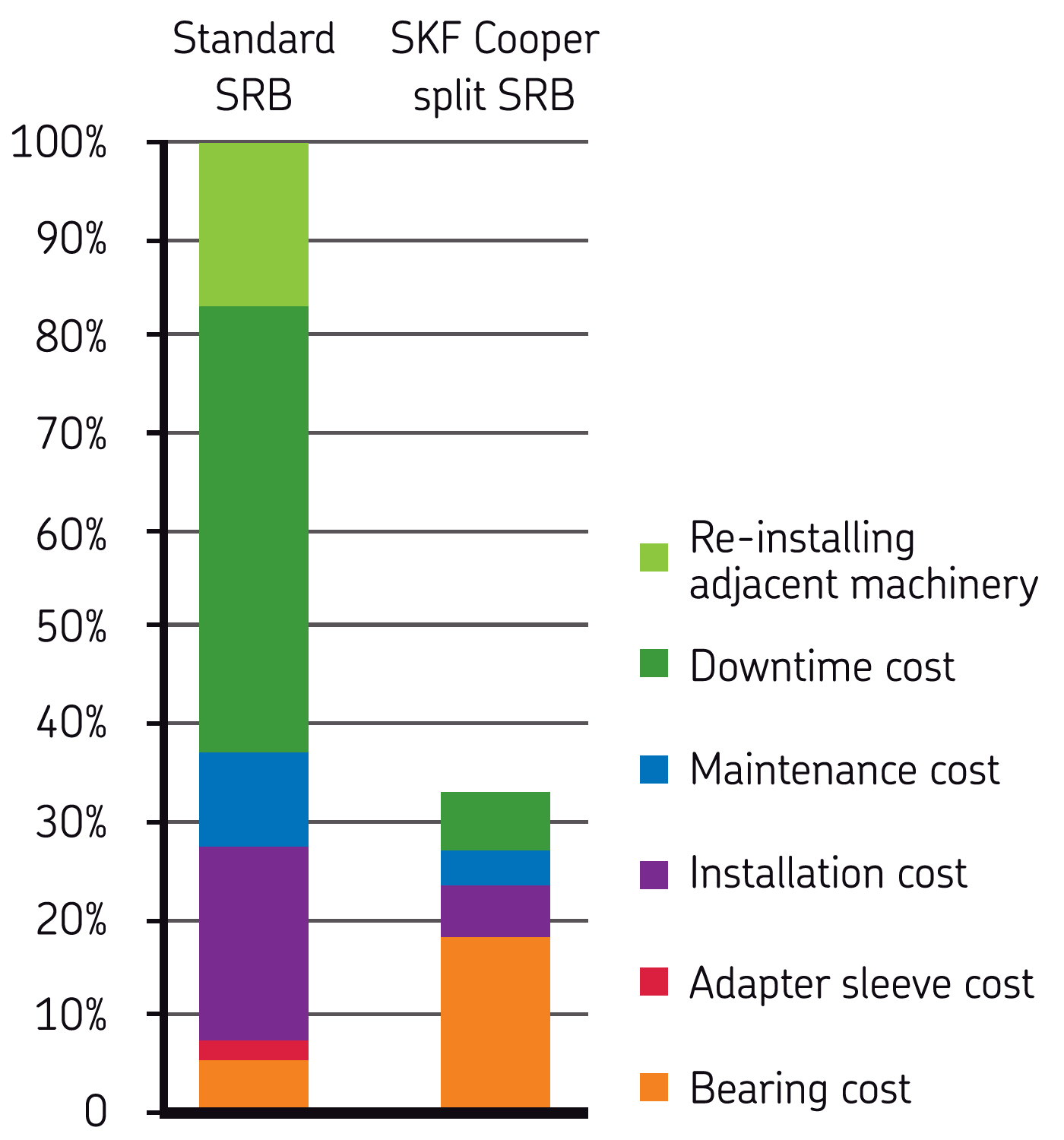

However you look at it – time is money!

It can take up to 24 hours to replace standard bearings compared to the eight hours it takes with SKF Cooper split spherical roller bearings. Take a look at our customer case to see how an Australian mining operation saved millions.

Features and benefits

- Allows safe and time saving in situ bearing replacements in the trapped position on conveyors pulleys, stacker re-claimers and other machinery

- Sealed variant available for increased protection against contamination and reduced maintenance

- Longer service life (MTBF) compared to other split bearings, thanks to the wire cut inner and outer ring manufacturing technique and sealed versions

- Sealed variant reduces grease consumption – and cuts environmental impact

- Compatible with SKF metric and inch split block housings

- Reduced risk of shaft fretting with better axial clamping

- Interchangeable with competitor split spherical roller bearings and split block housings

Boost worker safety

43% of accidents in the mining and cement industry are caused while workers perform maintenance or checks on conveyors. With the SKF Cooper split spherical roller bearings there is no need to dismount the drive coupling or the cantilevered drive to replace the bearing and so avoid realignment. This greatly reduces the risk to worker safety.

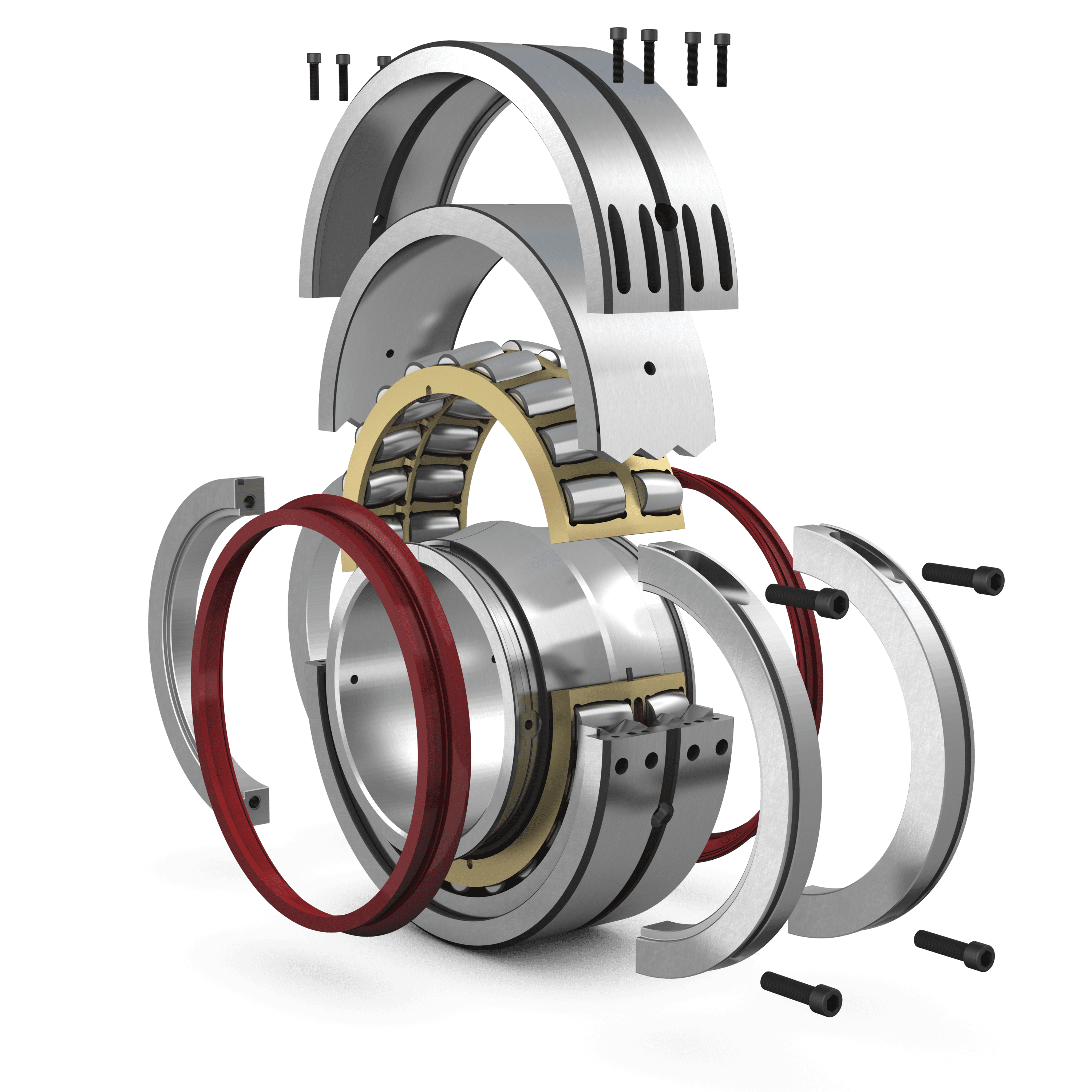

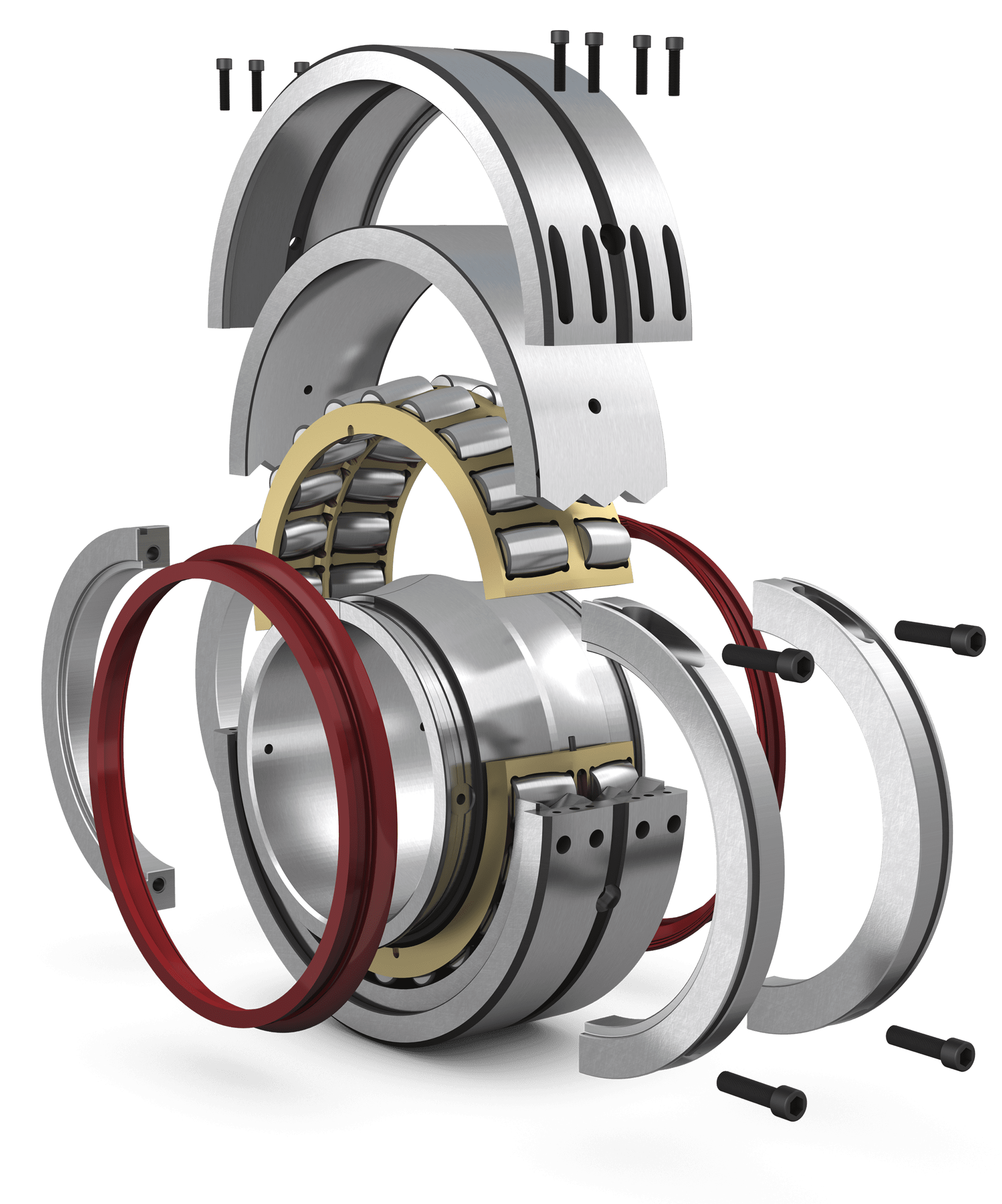

No comparison – modified features for improved alignment

Wire-cut inner and outer rings ensure an extra close fit that geometrically aligns the two halves, allowing rollers to transit from one half of the race to the other much more smoothly.

The outer race is designed with a ‘saw tooth’ joint which provides accurate axial alignment and the race itself is also thinner with a separate ductile steel ‘shroud’ which provides radial alignment.

|

|

Cost Savings

|

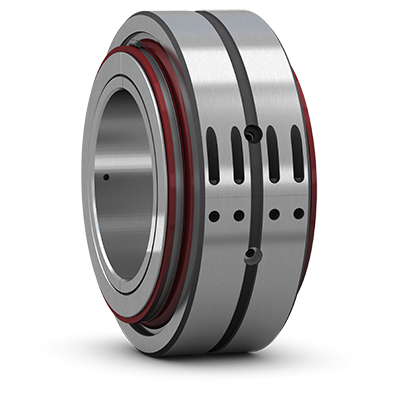

Sealed SKF Cooper split spherical roller bearings

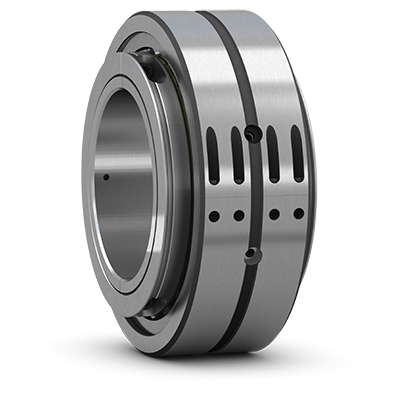

Open SKF Cooper split spherical bearings

|

Discover the ultimate bearing reliability

|

NB! If you’re looking for the ultimate in bearing reliability, take a look at the SKF Three-barrier

solution where contaminants are kept out by three barriers and lubricant is kept in.

|

Get the best from your bearings